PROUCTS CENTER

MLGRD-5000T Wire Winding Forging Press

Classification:

MLGRD series steel wire winding forging press

RD series products adopt a wire winding frame structure, with a bottom blank holder, reasonable layout, convenient operation, and fast workpiece speed. This series of products adopts finite element optimization design, with good rigidity and stable quality.

key word:Precision machinery

TEL:

- MLGRD-5000T

-

- 商品名称: MLGRD-5000T Wire Winding Forging Press

RD series products adopt a wire winding frame structure, with a bottom blank holder, reasonable layout, convenient operation, and fast workpiece speed. This series of products adopts finite element optimization design, with good rigidity and stable quality.

Product Description

RD series products adopt a wire winding frame structure, with a bottom blank holder, reasonable layout, convenient operation, and fast workpiece speed. This series of products adopts finite element optimization design, with good rigidity and stable quality. Mainly used for embossing of hardware products, moulding and other forming processes. Especially suitable for forging of radiator;

•Adopt fast liquid filling and fast pressure relief technology, fast pressurization speed and short pressing cycle

•Equipped with servo motor pump hydraulic control system, accurate, fast, energy saving and low noise

•Independent filter cooling device

•Photoelectric protection device

•Displacement sensor, precise positioning

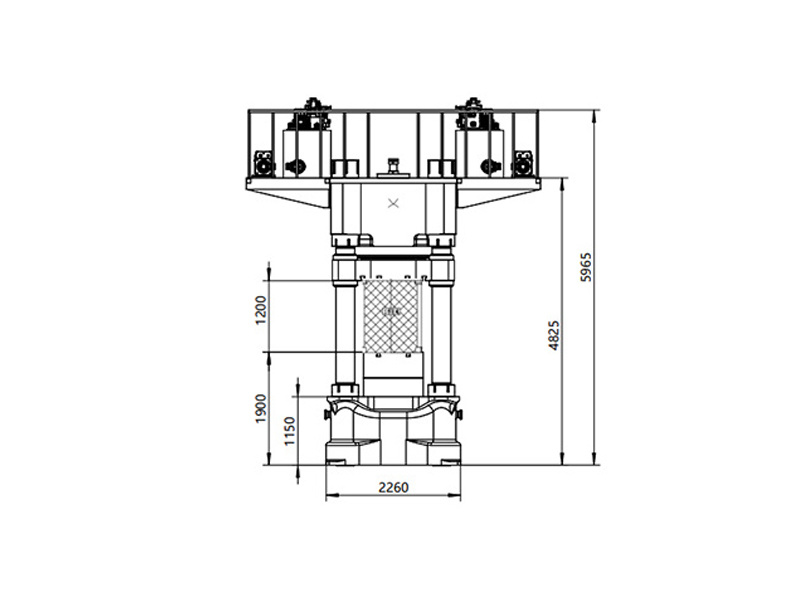

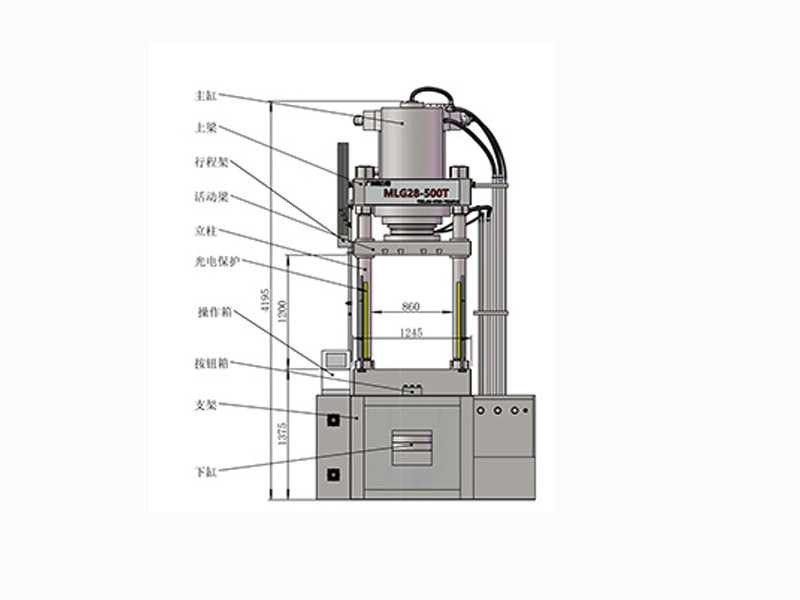

Outline

Physical Image

Product parameters (servo)

Serial Number Item Unit Data 1 main nominal force kN 50000 2 The maximum working pressure of the main cylinder MPa 80 main cylinder max working pressure 3 hydraulic system working pressure MPa 22 The hydraulic system working pressure 4 Max stroke of master cylinder ram stroke mm 400 5 Nominal force of return cylinder ejector force kN 960 6 Maximum row of return cylinder ejector stroke mm 80 7 Distance from movable beam to work surface max mm 1000 min mm 600 8 Lifting speed of movable beam downward mm/s 300 pressing mm/s June 9 return mm/s 300 9 otor power kW 90+90 10 pump flow L/Min xxx 11 Tablework left and right×front and rear (RLxFB) mm² 1200*1200 12 Effective area of movable beam left and right × front and rear (RL x FB) mm² 1200*1200 13 total weight Ton 74 14 Dimensions RL mm 3940 FB 2480 H 5790 - MLGRD-5000T Wire Winding Forging

Related products

Leave us a message

contact

Address:Merige, Michang 3rd Road, Enping City

Fixed line:86-0750-7826910 0750-7826912

Mail:mlipresszhu@126.com