PROUCTS CENTER

MLGR-4000T steel wire wound machine

Classification:

MLGR series steel wire winding machine

The R series products adopt a steel wire wound frame structure, and the lower sideline is placed. The layout is reasonable, the operation is convenient, and the workpiece speed is fast. The main oil cylinder uses the early warning steel wire wrap structure. Under high pressure conditions, high life, good anti -fatigue performance, and good safety performance.

key word:Precision machinery

TEL:

- Product description

-

- 商品名称: MLGR-4000T steel wire wound machine

The R series products adopt a steel wire wound frame structure, and the lower sideline is placed. The layout is reasonable, the operation is convenient, and the workpiece speed is fast. The main oil cylinder uses the early warning steel wire wrap structure. Under high pressure conditions, high life, good anti -fatigue performance, and good safety performance.

Product Description

The R series products adopt a steel wire wound frame structure, and the lower sideline is placed. The layout is reasonable, the operation is convenient, and the workpiece speed is fast. The main oil cylinder uses the early warning steel wire wrap structure. Under high pressure conditions, high life, good anti -fatigue performance, and good safety performance. This series of products adopts finite element optimization design, with good rigidity and stable quality. It is mainly suitable for molding processes such as hardware products, compound models and other molding processes. It is especially suitable for the squeezing and thinning of the molding aluminum cooker and the forging of the radiator.

• Use fast charging, fast pressure relief technology, fast pressure speed, short -pressing cycle

• Equipped with a servo motor pump hydraulic control system, accurate, fast, energy saving, low noise

• Independent filtering cooling device

• Optical protection device

• Shift sensor, precise positioning

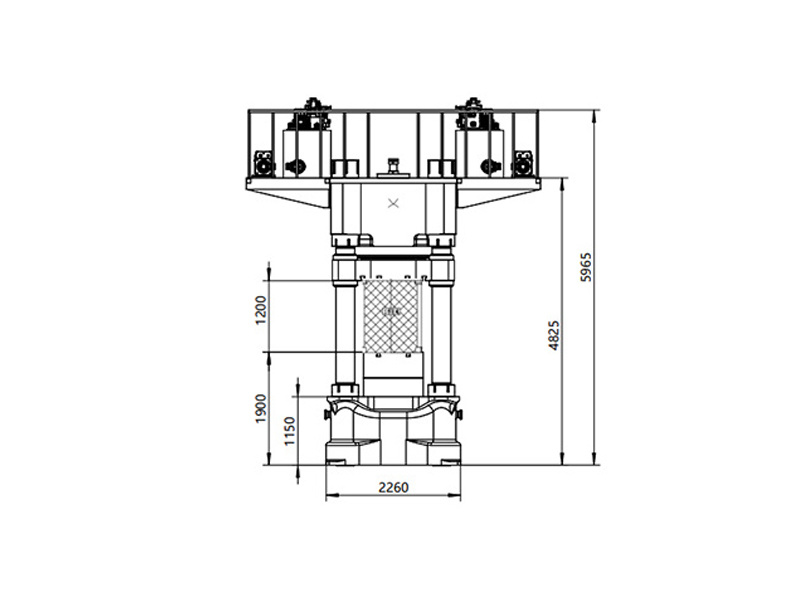

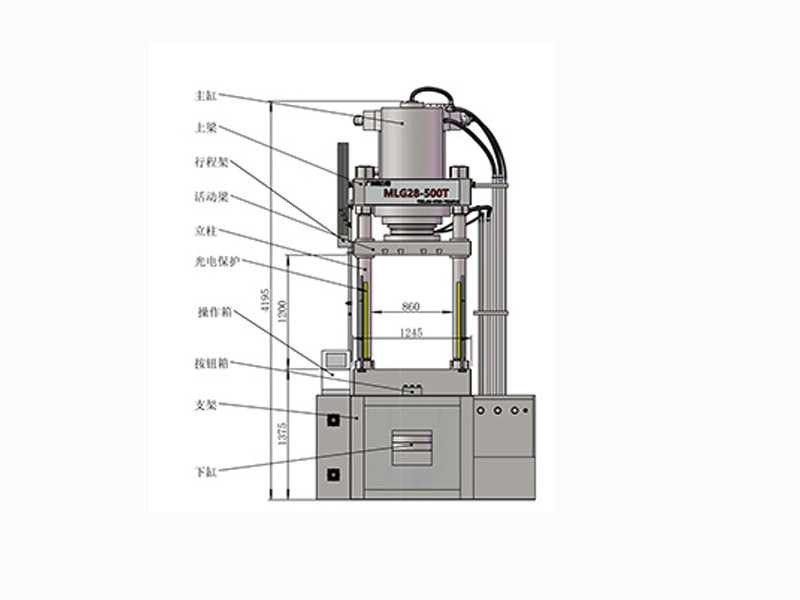

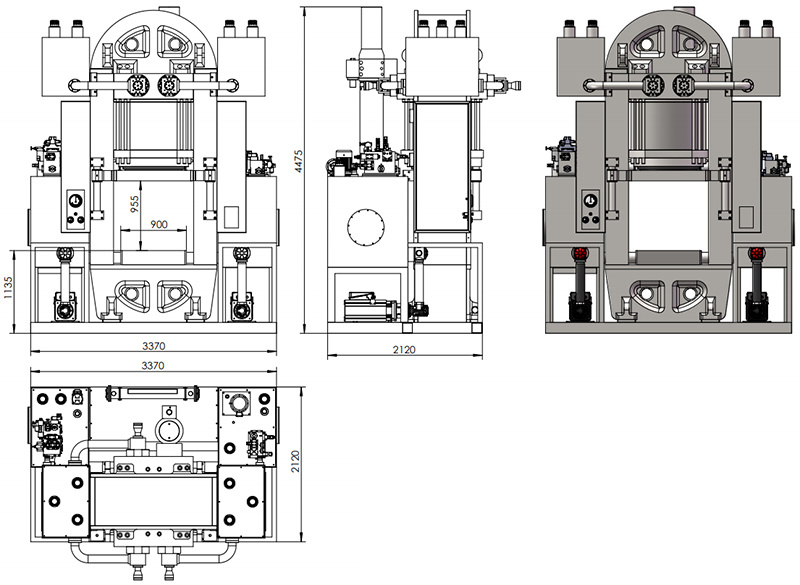

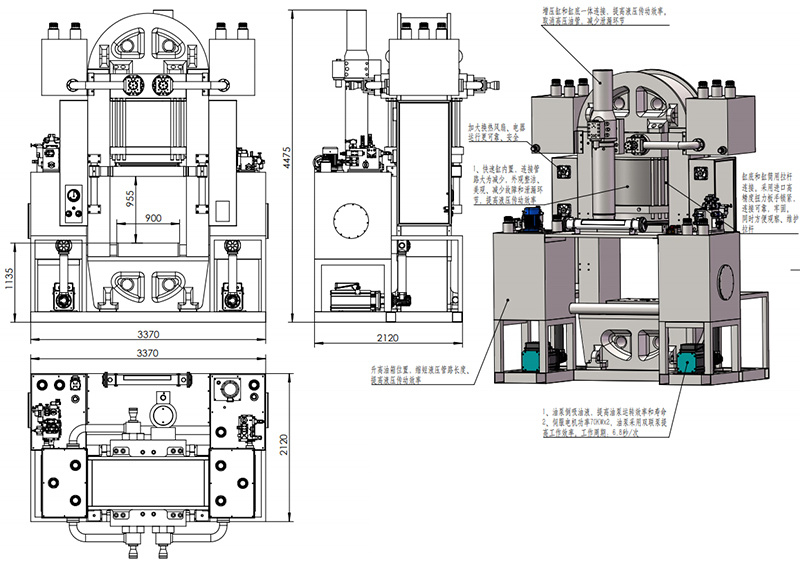

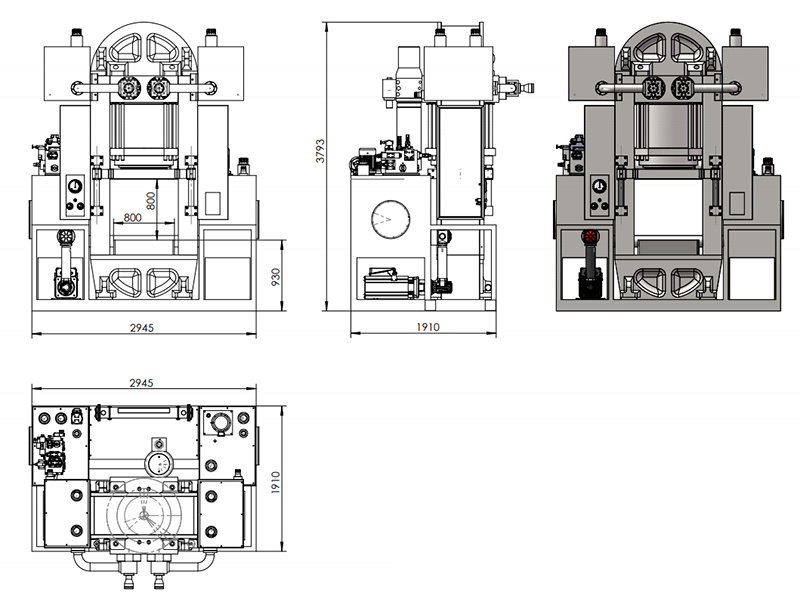

Outline

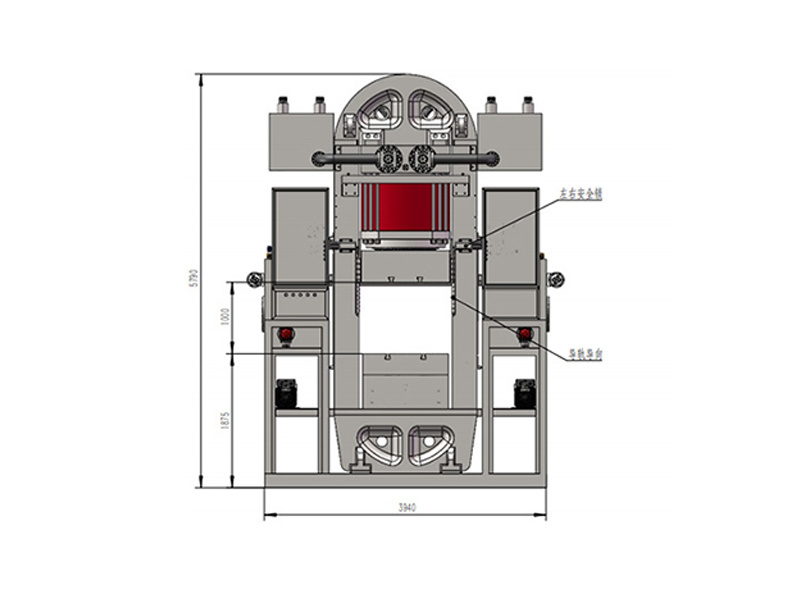

Physical Image

Product Parameters (servo)

Serial Number Project Unit Data 1 main nominal force kN 40000 2 main cylinder max working pressure MPa 80 3 The hydraulic system working pressure MPa 20 4 ram stroke mm 350 5 ejector force kN 120 6 ejector stroke mm 50 7 open height max mm 950 min mm 600 8 ram speed downward mm/s 265 pressing mm/s 20 return mm/s 265 9 motor power kW 70+70 10 pump flow L/Min xxx 11 The effective area of the workbench Tablework left and right × front and back (RLXFB) mm² 950*780 12 The active area of the active beam × front and back (RL X FB)

The activity crossbeam ehective areamm² 1080*1080 13 total weight Ton 43 14 Overall dimension RL mm 3300 FB 2400 H 4400 15 A single working cycle (90%output force, 220mm itinerary) s 6.5 16 Oil tank volume (No. 68 anti -abrasion hydraulic oil) Lift 2200 (11 barrels) - MLGR-4000T steel wire wound mach

Related products

Leave us a message

contact

Address:Merige, Michang 3rd Road, Enping City

Fixed line:86-0750-7826910 0750-7826912

Mail:mlipresszhu@126.com